There are many methods and machines capable of cutting parts, but one of the most effective, efficient and affordable approaches is known as water jet cutting. Water jet cutting is the preferred operation for many manufacturers looking to cut high-quality parts without adverse material effects that can come into play when relying on other cutting methods.

A water jet uses a concentrated mixture of water and garnet (fine sand) that is sprayed through a small orifice at extremely high pressure (50,000-60,000 psi.) The result is an extremely fine cutting stream, capable of passing through nearly any type of material with little hardness/thickness restrictions. As with other CNC style machines, a water jet uses CAD data to follow designated tool paths as well as varying cut types/qualities to adjust for speed, depth of cut, etc.

The water jet is an incredibly effective piece of machinery, and it is gaining popularity across the industry as more manufacturers and engineers are learning of its unique capabilities and benefits. Below, we will dive deeper into several of the advantages of water jet cutting, as well as how the water jet stacks up against more conventional cutting options.

It Can Cut Thicker parts

One of the biggest advantages of cutting on a water jet is that you are not limited by material thickness. The water jet can fly through thin material with ease, and operators will often create layered stacks of thin stock so the water jet can cut through several sheets at once. This method can help reduce production time and increase material yield without sacrificing cut quality.

The real advantage of the water jet comes into play on thicker materials. While other cutting methods may start to lose performance/quality anywhere from 1/2” to 2” in limited materials, the water jet is able to reliably cut up to a mind-blowing 15” thick stainless steel. This truly separates the water jet from its competition. Think of the time that can be saved on secondary machining operations by water jet cutting high-quality profiles in thick material, or by using a water jet to modify existing parts that would otherwise be too thick for other machines to handle.

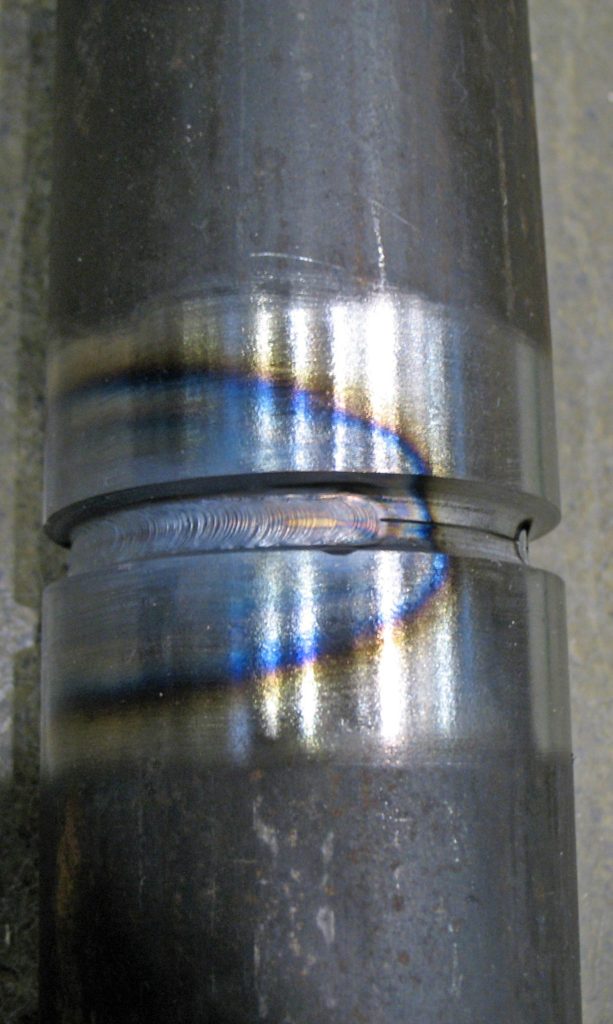

No heat created in cutting

Another unique advantage that the water jet provides is the ability to cut parts without creating any heat. This has a number of benefits when it comes to material selection and secondary operations.

In many instances, heat can spell trouble in machining. When cutting softer materials, too much heat will result in melting, warping, discoloration and other negative side effects that will adversely affect a finished part. On harder materials, added heat will actually change the physical make up of plate/stock making it far more difficult to machine during secondary operations.

When a customer wants to feel confident that their material will be cut without losing any structural integrity due to effects from heat, they choose the water jet every time.

Can cut almost any material

We’ve already established that thickness and heat are not limiting factors when it comes to water jet cutting. So, does that mean that a water jet can cut virtually any material? The answer is….pretty much, yeah. The ability to cut a wide range of material is yet another benefit of water jet cutting that makes it one of the most versatile machines in any shop.

The water jet can cut a seemingly endless list of organic and inorganic material. Ferrous and non-ferrous metals of all types are some of the most commonly cut materials on a water jet, including brass, copper, aluminum, titanium and a wide variety of steels. The water jet is equally effective at cutting more abstract materials such as plastic, rubber, wood, tile, stone, glass, and more. The water jet is even used in the food industry to cut out custom cakes and pastries and to slice bread.

Very little fixturing

Some CNC machines require lengthy setups with complex fixturing that can take hours to install and calibrate before a single chip is cut. The water jet, on the other hand, requires very little in terms of fixturing and can be set up and running in minutes instead of hours.

Whether a job calls for a large sheet of material, or you just need to cut a small part from an existing remnant, the water jet generally only requires a handful of clamps, weights for brackets to secure material in place. After that, it’s just a matter of establishing zeroes and loading a program. A skilled operator can have the process completed in no time, making set up costs next to nothing.

The quick set up and limited fixturing on a water jet can be a real benefit to the customer. Depending on the size of the job, most shops can offer significantly shorter lead times on water jet work which can be a huge difference-maker when it comes to reducing costs and expediting production.

Waterjet Cutting Vs The Alternatives

Waterjet Cutting vs Plasma

Plasma is another commonly used method for cutting certain materials, but it is far more limited than the water jet. It uses a series of gas/consumables to create a plasma arc that corrodes material along a path. Plasma can quickly cut through certain ferrous/non-ferrous metals, but it can not cut non-conductive materials like plastic. Plasma also introduces a great deal of heat which limits it’s cutting capabilities to select materials/thicknesses before melting and work hardening occurs. Plasma cutters will omit gaseous fumes when cutting so precautions must be taken for proper ventilation.

Waterjet Cutting vs Laser

Laser cutting is a highly efficient cutting method that rivals the water jet in many areas. It is able to cut with more speed and precision, but it is limited as to what it can cut. The laser also introduces heat into its parts which can lead to melted material and work hardening. Laser may be a more effective method for cutting certain thin metals, but the benefits and advantages of the water jet remain outmatched due to its broad versatility across applications.