It’s an exciting time to be a part of the manufacturing world. Innovative technologies are becoming more mainstream, and machines/processes that once seemed like science fiction, are now readily available for a wide range of shops, customers and enthusiasts.

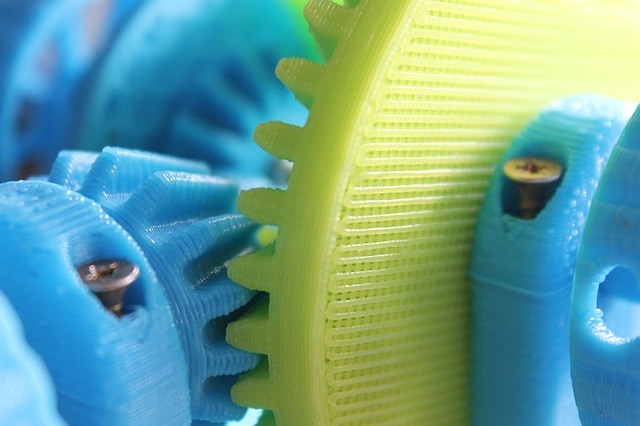

Some of the most exciting advancements have come in the way of CNC Machining and 3D printing. While their processes differ, each have robust capabilities that can be utilized to manufacture complex parts with exceptional quality and precision.

Additive Manufacturing vs Subtractive Manufacturing

The primary factor that distinguishes CNC machining and 3D printing is essentially addition vs subtraction.

When using a CNC machine, one is starting with a piece of defined stock (or blank) and using cutting tools to remove excess material so that what is left over is the finished part. This process is known as subtractive manufacturing.

Both 3D Printing and CNC Milling are highly effective, but there are some key differences between the two

Conversely, a 3D printer does not start with any stock work piece, and instead adds material (usually layer by layer) until the finished part is complete. This process is known as additive manufacturing.

Differences Between 3D Printing and CNC Milling

Both 3D Printing and CNC Milling are highly effective, but there are some key differences between the two that should be noted. Understanding these differences can help users determine the best approach for their application, and often times, both can be utilized to speed up processes and improve production.

Accuracy/Finish

One area where there is some noticeable separation between CNC Machining and 3D Printing is dimensional accuracy. CNC machines are able to hold and maintain a higher degree of precision across multiple axis, with tolerances as tight as a single micrometer. Because CNCs are generally working with more rigid materials, tools, work holding, etc. they are able to execute incredibly precise machining operations over and over again.

Parts machined on a CNC will also have a better surface finish than those manufactured on a 3D printer. The subtractive process allows for a greater range of control, and can produce mirror surface finishes if desired.

That said, 3D printers have made great strides in their ability to hold tighter tolerances and to maintain a higher degree of surface quality. Many 3D printers can produce parts within thousandths of an inch of a desired dimension, but they require more fine tuning and are ultimate less repeatable than their CNC counterpart.

While 3D printers cannot produce parts with the same degree of surface finish as a CNC, many 3D printer professionals have become extremely skilled in finishing their work pieces (sanding, polishing, painting, etc.) The end results are truly impressive and comparable to a machined piece, though it does take added time to achieve these results.

Size of Parts

CNC Machines and 3D printers come in all shapes and sizes, and can produce parts both large and small. Though CNC machines generally come with a larger machining envelope, there are 3D printers big enough to print an entire car or house (though these types of printers may not be practical for the average shop/consumer)

Most entry level printers will come with a print window around 8”-12” cubed. For larger parts, it is not uncommon to print individual components/sections and then assemble after completion. This is a simple workaround if size of printer is a limiting factor. Printers can also print very small and intricate parts. It can be a huge time saver to produce a scaled down component on a 3D printer as a proof of concept or working prototype prior to machining a full sized piece on a CNC.

CNC machines are generally capable of producing much larger parts. The standard CNC will have a larger footprint and cutting window than a 3D printer, and many are so massive that they must be built on-site. That said, there has been a recent push for CNC machines with a smaller footprint, and many are compact enough to fit on a counter or desktop.

Speed

When looking at CNC machines vs 3D printers, speed should be viewed in two categories – setup and machine time.

CNC machines are lightning fast. Many can fly through hardened material with ease, and are capable of producing hundreds, even thousands of parts in a given shift. Advancements in tooling, work holding and machine design have led to huge leaps in machining speed, making CNCs the go-to staple for part production.

The draw back to the CNC is that it requires more set up time than a 3D printer. Operators must load tools, fixtures, stock material, etc. and this process can be quite time consuming. 3D printers, on the other hand, require very little setup time. Assuming the printer is leveled/calibrated, starting a print is usually as simple as loading a file and clicking a button.

While there are printers on the market that boast impressive print speeds, 3D printers are still relatively slow in comparison, and are generally used more for prototyping than production. A part that can be machined in minutes on a CNC could take several hours on a 3D printer.

Materials

Both CNC Machines and 3D printers can make parts using a wide variety of material.

CNC machines have very few material limitations. They can machine parts out of metals, plastics, wood, stone and more.

3D printers usually print some type of plastic (ABS, PLA, Nylon) although there are printers on the market capable of printing different metals.

Price

3D printed parts are generally cheaper for a variety of factors. The machines themselves cost less. They require very little setup time, and utilize inexpensive raw materials (a spool of PLA is less than $20.) There is less wear and tear associated with 3D printers, and they don’t require expensive tooling to machine parts. 3D printing can be a very cost effective approach for small/prototype parts, and many schools and libraries offer 3D printing services for a minimal fee.

Parts produced on a CNC machine can be more expensive, but much of that depends on part quantity. CNC machines can be pricey, and require tooling, setup time, maintenance and skilled operators which can all lead to a higher price tag when running small batches of parts. On the flip side, the speed, precision and quality of a CNC machine is unparalleled. When running larger quantities, the price per part can drop significantly making it an extremely affordable and efficient means of production.

Advantages of CNC Machining and 3D Printing

The advantages/disadvantages of each CNC Machining vs 3D printing depend entirely on the types of parts one is looking to produce, and how those components will be used in the field. As 3D printing technologies continue to advance, there will be increased crossover between applications more shops will utilize both methods to respond to customer demands.

CNC Machining

- Price – more cost effective when production large quantities of parts

- Quality – able to hold tightest tolerances with best surface finishes

- Speed – more set up time, but significantly high production speeds

- Materials – very few limitations in materials that can be machined

- Size – much wider machining envelope, can product parts large and small

3d Printing

- Ease of use – little set up time, minimal learning curve

- Price – inexpensive machines/raw materials, low cost of use

- Environmentally friendly – less waste, only printing what is needed

- Machining capabilities – 3D printers can perform operations that are currently impossible for a CNC machine (printing functioning chains/screws, printing semi-hollow geometry, etc)