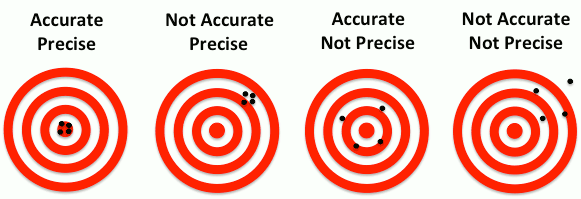

Advancements in manufacturing technology are opening up new possibilities for the types of parts that can be designed and machined. Improvements in the accuracy and precision of machine tools have allowed for the parts to be created with much tighter tolerances that can be held over dozens, hundreds or even thousands of part cycles. But what do we mean when we talk about accuracy? What does precision really mean in the manufacturing world? Knowing the difference between accuracy and precision in machining can help you design better and more affordable parts, and ensure that your desires meet expectations when it’s time to get them made.

Accuracy

What does accuracy mean in terms of machining? Simply put, an accurate machine will execute an operation (cut, drill, bore, etc.) the way that the operator/programmer intends. If the CNC tells the machine to drill a hole at 5” from the outside edge, the machine will perform this step at exactly 5” without issue.

Precision

If accuracy is how close a CNC can perform an operation to a given parameter, precision has to do with repeatability of a said operation. Consider a production manufacturing environment, where parts are being machined in the thousands. A highly precise machine will maintain the same degree of accuracy on the five hundredth part as it did on the first. If part dimensions varied wildly across the batch, this would point to a serious lack of precision and would be a real pain for the machine operator. That said, even if a machine is not accurate and it’s completed dimensions vary from what was programmed (i.e. a hole is to be drilled 3” from an edge and it is drilled at 3.02”,) it can still be precise if it is able to consistently repeat that procedure of a large series of parts.

Most modern CNC tools can repeatably hold programmed dimensions without issue, but it’s important to consider the level of accuracy/precision needed when designing and manufacturing a part. Certain components will need to hold extremely tight tolerances over large quantities, but this can require extra time, setup, inspection, etc. when machining so in many instances, higher accuracy is not worth the added cost to manufacture.